Construction

Construction of the project will involve detailed, specialist engineering techniques. The main principles are outlined below.

Wind turbines

We are proposing to use three-bladed wind turbine generators. These will include the following elements:

- Rotors, including blades and a hub (connects the blades to the shaft and drive train).

- Nacelle, which houses the electrical generator, control electronics and drive system.

- Structural support, which includes a tubular steel tower on top of a foundation structure.

The layout and design of the wind farm

The exact layout of the wind turbine generators is still being developed and will not be finalised until the project has been granted consent by the Secretary of State.

Wind turbine generators will be set out in two ‘lines of orientation’ through the array area and our wind turbine rows will be orientated roughly north to south. In-row (the space between each individual wind turbine generator in a row) and interrow (the space between each row of wind turbine generators) spacing will be a minimum of 1400 metres.

To promote co-existence with fishing activities, we are committing to maintaining an area that will be free of wind turbines and offshore substation platforms.

Connecting offshore to onshore – Transition Joint Bays

The offshore export cables will connect to the onshore export cables at up to four Transition Joint Bays (TJBs).

Fast facts: wind turbine generators

The below information is based on current understanding and may be refined as we progress through the DCO process. These numbers are assuming the generation of 1.5GW of electricity.

- Proposed number of wind turbine generators: up to 96

- Proposed rotor diameter: 320 metres

- Maximum blade tip height of wind turbine generators: 364 metres above the lowest astronomical tide (LAT)

- Proposed rotor clearance above LAT: 34 metres

Fast facts: Offshore Substation Platforms

- Proposed maximum number of OSPs: 4

- Proposed maximum topside width (’topside’ meaning the main structure on top of the foundations above the sea surface): 60 metres

- Proposed maximum topside length: 80 metres

- Proposed highest point of topside (above LAT), excluding the helicopter landing pad and lightning protection: 70 metres

Onshore cables

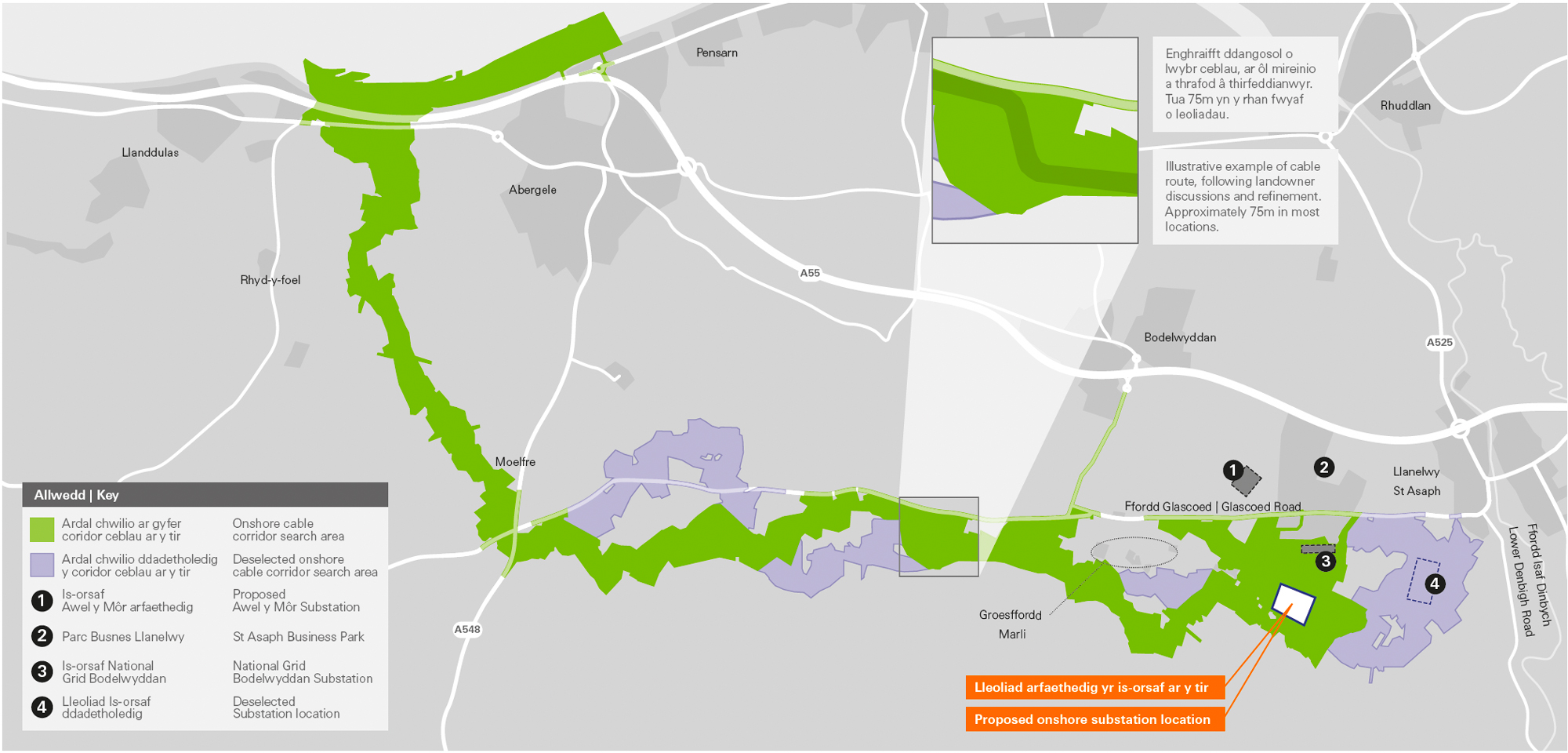

The Mona Onshore Cable Corridor will be approximately 15km in length, with a width to allow up to four cable circuits to be installed. The cables will be buried underground. The Mona project team have chosen our single onshore cable route and will continue talking to landowners, in order to further refine down our cable corridor to one that is approximately 74m wide.

The map below illustrates these refinements.

Once the cable installation work is completed and commissioned, the temporary haul road will be removed and the ground reinstated using stored subsoil and topsoil. All temporary construction compounds and temporary fencing will be removed, field drainage and/or irrigation will be reinstated and the land will be restored to its original condition. Where practicable, consideration will be given to early restoration of sections of the Mona onshore cable corridor.

Hedgerows will be replanted using locally sourced native species, where practicable. Suitably qualified and experienced contractors will be used to undertake the reinstatement, which will be based on restoring the hedge to match the remaining hedgerow at each location. Where appropriate, some enhancement (such as planting of additional suitable species) may be undertaken.

Although the Mona Offshore Cable Corridor and Access Areas have been identified, the exact route of the offshore export cables is yet to be determined and will be based upon geophysical and geotechnical survey information.

Onshore substation

A temporary construction compound will be required at the Mona onshore substation. The compound will be located within the Mona Proposed Onshore Development Area and will provide offices, welfare facilities, storage of plant and equipment and parking for construction staff.

It is anticipated that construction access to the onshore substation site will use the proposed permanent access route, albeit that during construction, a temporary surface may be used. This access route will need to be installed early in the construction process.

The onshore substation building substructures are likely to be composed of a steel frame and cladding materials. The structural steelwork will be fabricated and prepared off site and delivered to site for construction.

Construction access points

Access points will be required from the public highway to the Mona Onshore Cable Corridor and construction compounds. Temporary access points off the highway will be installed to facilitate vehicle access from the highway to the Mona Onshore Cable Corridor and temporary construction compounds during construction.

A temporary haul road will be installed within the Mona Onshore Cable Corridor to reduce the number of HGVs associated with the Mona Offshore Wind Project travelling on the public highway. The haul road will be around 6m wide and provide vehicle access from the temporary construction compounds to the Mona Onshore Cable Corridor. It will be constructed early in the construction programme and will be used where needed throughout the installation of the onshore export cables and Mona Grid Connection Cable.

Further work

Prior to the commencement of all of our onshore works, a number of preconstruction surveys and studies will be undertaken to inform the design teams when developing the final design, including:

- Archaeological pre-construction work

- Ecological pre-construction surveys

- Geotechnical investigations

- Drainage studies

Code of Construction Practice

All construction will be undertaken in accordance with a Code of Construction Practice (CoCP). The CoCP will set out the key management measures that we will require all our contractors to adopt and implement for all relevant construction activities relating to the onshore elements of the Mona Offshore Wind Project.

The CoCP will be developed in dialogue with our stakeholders. It will remain a draft document during the Examination process and will be finalised when we have a detailed design post-consent. Implementation of the CoCP will be secured through the DCO requirements.